How to measure & choose the correct window lock mechanism.

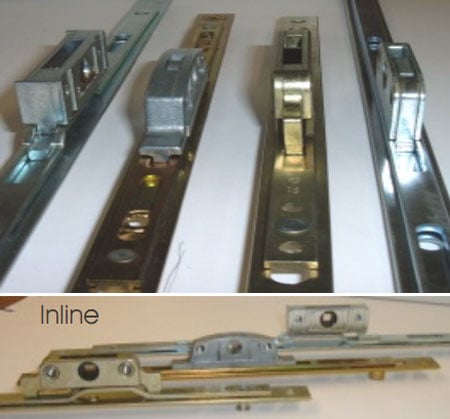

First of all there are two types of locks Inline and Offset. Generally speaking most modern systems are fitted with the inline version as shown below. However in older systems it was common to use the Offset versions as also shown below. It is relatively easy to identify the right lock to replace your broken one by following our step by step process. Remember it does not really matter about the make of the window lock, it is more important to get the size and type right as most makes are easily interchangeable with very little effort.

Inline lock mechanisms have the gearboxes located in a central position under the faceplate.

Generally you will find that inline rods are on a flat plate (always exceptions of course!) You will find the sizes and details for these attached to our actual item parts (on-line) simply check these against yours.

Offset lock mechanisms

Offset lock mechanisms have the gearboxes located to the edge position under the faceplate (I:E. Off centre)

There are two types of offset rods. U-track (sometimes called c-track)

and Flat. You will find the dimensions and info for these attached to our actual item parts simply check these against yours to get the right one.

How do I measure the backset on my window lock mechanism ?

Now you have identified the type of lock rod mechanism that you are wanting to replace all you need now is to identify the

Backset dimension / Length of the lock mechanism / and finally the type of locking points you need. Below you will see the

information you need and how to quickly get it.

How do I measure the length of my window lock mechanism?

Measure the full length of the lock mechanism to identify the length you require. You will find that as a rule dimensions start at 400mm and increase in 200mm increments up-to 1200m.

End Result

By using the information in this document you will be able to identify the correct lock for your situation. It is often the case that you will find the existing manufacturer has either ceased trading or dis-continued the lock mechanism. However this is not a major problem as long as you get the in-line or offset type right and then the matching dimensions and type of lock points right. If the Lock points are found to be in a different position on the lock faceplate, All you normally need to do is re-position the keep plates (the metal plates that the lock points fasten into) which is only a matter of un-doing 1-2 screws and re- positioning them to suit the new lock.

Generally you will find that inline rods are on a flat plate (always exceptions of course!) You will find the sizes and details for these attached to our actual item parts (on-line) simply check these against yours.

Generally you will find that inline rods are on a flat plate (always exceptions of course!) You will find the sizes and details for these attached to our actual item parts (on-line) simply check these against yours.

Offset lock mechanisms have the gearboxes located to the edge position under the faceplate (I:E. Off centre)

Offset lock mechanisms have the gearboxes located to the edge position under the faceplate (I:E. Off centre)

There are two types of offset rods. U-track (sometimes called c-track)

and Flat. You will find the dimensions and info for these attached to our actual item parts simply check these against yours to get the right one.

There are two types of offset rods. U-track (sometimes called c-track)

and Flat. You will find the dimensions and info for these attached to our actual item parts simply check these against yours to get the right one.